GLASS TEMPERING

DIAMOND TEMPERED, STRONGER THAN THE REST.

As the final and most important step in the glass fabrication process, tempering glass creates a finished product that is 4 to 5 times stronger than annealed glass. The process starts by heating the glass to 620° Celsius followed by a monitored rapid cooling process called quenching. This drastic change in temperature creates a tension within the interior of the glass, while the outer surface goes into a compression. This difference between the two work together to create the signature strength seen with tempered glass.

To ensure the tempering process in being conducted properly, Consolidated Glass Corporation is third party certified by the Safety Glazing Certification Council, or SGCC. This certification, alongside our state-of-the-art tempering oven and experienced operators, allow us to produce the some of the highest quality tempered glass in the industry. With the capability to handle thicknesses from 1/8” to 3/4" and oversized pieces up to 95 5/8”, Consolidated Glass Corporation is the best choice for your glass fabrication needs.

SAFETY IS OUR PRIORITY.

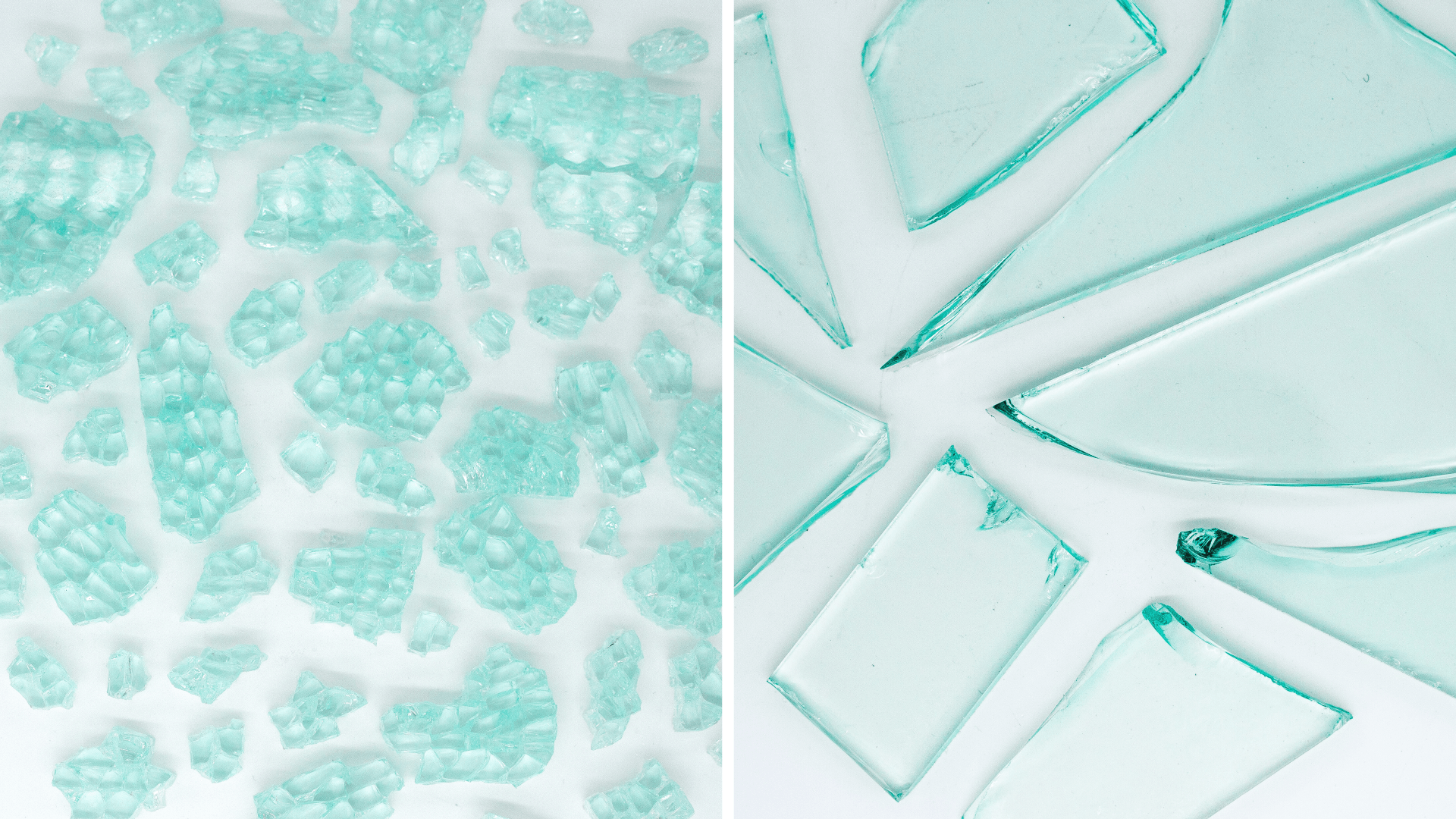

Not only does the tempering process create a stronger glass, but it also allows for a safer product. When broken, annealed glass will shatter into large, jagged shards, resulting in a higher threat to anyone around. With tempered glass, the layers created in the heating and cooling process allow for a much safer break pattern when a failure of glass occurs, breaking off into small, relatively harmless pieces.